|

Shaft Seal |

Description |

Advantages |

Disadvantages |

|

Braided

or formed rings that are compressed in the stuffing box of the pump.

As the packing is tightened, it compresses against the shaft and

stuffing box bore to create the seal. |

- Economical

- Excellent for sealing thick,

difficult to seal liquids such as chocolate, molasses, asphalt,

resins, tar, and some adhesives

- Seldom catastrophically fails

|

- Poor seal for thin liquids,

especially at higher pressures

- Requires lubrication either

externally or by the liquid being pumped; this means packing must be

allowed to leak slightly (weep)

- Can damage the pump shaft if

adjusted too tightly

|

|

A

circular elastomeric seal element in a rigid outer housing |

- Economical

- Come in a wide variety

including cartridge triple lip seals for higher viscosity liquids

|

- Typically limited to lower

pressures

- Poor for thin, non-lubricating

liquids or for abrasives

- Can catastrophically fail

|

|

Simplified, mechanical seals use highly polished faces (one stationary

and one rotating) running against each other* to form a seal.

*actually, seal faces only

touch when at rest. While turning, they are separated by a thin

film of the liquid being pumped, barrier fluid, or gas |

- Mechanical seals come in a

wide variety of designs and materials for nearly every application.

- Offer designs which can be

easily replaced or repaired

|

- Like lip seals, can

catastrophically fail

- Higher end double cartridge

seals and gas barrier seals are quite expensive and require external

support equipment.

|

|

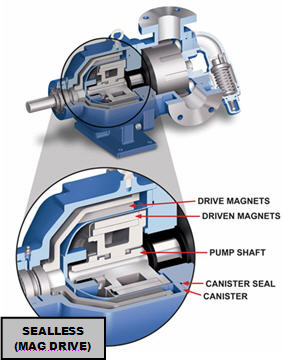

A Mag

Drive pump is a sealless pump that utilizes a magnetic coupling to

create a static shaft seal. Drive magnets (outer) align with

driven magnets (inner) and use magnetic force to turn the shaft through

a static containment shell (canister). |

- Mag Drive pumps are a truly

sealless design which ensures zero leakage of liquid or emissions,

making them ideal for hazardous, toxic, corrosive, flammable, or

expensive liquids.

- Extremely reliable for maximum

insurance against seal leakage and maximum seal life

|

- More expensive than most shaft

seal options, but this must also be weighed against the added costs

of seal replacement, including labor and cleanup.

- Typically limited to about

500°F / 260°C maximum (heat can permanently damage the magnets)

- Based on the cost and risk of

damage due to heat, monitoring devices are typically recommended to

protect these pumps from damage.

|